Rotary PET blow molding machines represent the next generation of high-performance, high-volume bottle production systems. Unlike linear machines, rotary systems are designed for continuous circular motion, offering unmatched speed, precision, and efficiency.

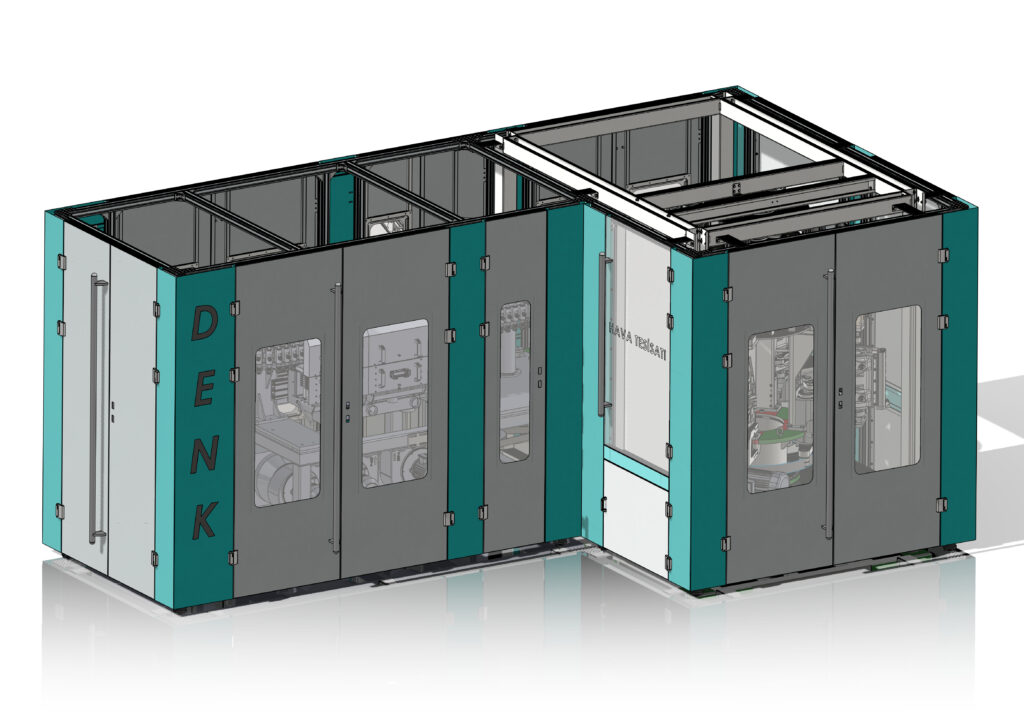

Denk Makine’s rotary PET blow molding machines are fully compatible with filling and capping systems, creating seamless Combi Block production lines. With optimized drive systems, advanced infrared heating, and reduced energy consumption, they provide superior bottle quality while minimizing operating costs.

Advantages of Our Rotary Machines

High productivity with up to 1,300 bottles per cavity per hour

Energy efficiency, consuming 15% less energy than conventional systems

Compact footprint, requiring 50% less floor space compared to separated systems

Easy maintenance with modular design and reduced wear components

Full rPET compatibility for sustainable and eco-friendly production

Rotary machines are the ideal solution for beverage and food industries that demand high-speed, large-scale, and cost-effective production, while ensuring sustainability and long-term reliability.

5 - 7 LT Capacity Series

Fully automatic rotary stretch PET blow molding machines with a capacity of 5200 to 7200 bottles/hour for bottles.

Denk Makine’s fully automatic rotary PET blow molding machines for the 5–7 liter range offer production capacities from 5200 to 7200 bottles per hour.

Equipped with advanced stretch-blow technology, they deliver durable and consistent bottles with optimal performance.

This series is the ideal solution for medium-size bottle production, combining energy efficiency, reliability, and flexibility for a wide range of applications.

Optimum and Stable Operation

DENK Makine stands out in the sector by offering more economical, performance, scaled and efficient machines than the machines available in the market.

DENK Academy Digital Platform

DENK Makine, which quickly educates its customers about the machines it manufactures, encourages continuous learning with its digital platform called DENK Academy.

Fast Information Sharing and Maintenance Operations

DENK Makine provides uninterrupted support to its customers by sharing information quickly in terms of maintenance operations and efficient use.

Widespread Service Network and Annual Maintenance Agreements

DENK Makine, which persistently aims to establish a widespread service network, protects its customers from surprise expenses with annual maintenance agreements.

Enhancements Supported by Digital Resources

DENK Makine focuses on continuous improvement by sharing improvements in machine maintenance and operations with its customers through digital resources available on its website.

Original Designs and Recycling

DENK Makine, which attaches importance to original design in the machines produced, offers environmentally friendly solutions by keeping the recovery rates high.

Customer-Oriented Personalized Approach

With nearly a quarter of a century of experience, DENK Makine adopts personalized approaches to solve the needs of its customers in advance and offers optimum price/performance solutions with its trust-oriented commercial approach.

Sustainable After Sales Technical Support

DENK Makine has achieved great success with its sustainable after-sales technical support services for the continuity of all the products it has produced in the past.

Belief in the Work Team

DENK Makine's biggest difference is its trust in its work team. The achievements that emerge with the contribution of teammates reflect the understanding of maximum efficiency in the business ecosystem.

Intellectual Capital Focus

DENK Makine considers the intellectual capital of business stakeholders as the largest and most critical capital and therefore supports it with extra in-house trainings.

Learn more about our process

Step 1

Parameters such as volume determination, preform design, bottle design and production capacity are received from the customer and the preliminary work process is started.

Step 2

The type of machine to be manufactured is determined based on the parameters taken from the preliminary work process.

Step 3

Options such as air recovery and additional formwork are determined and a bidding process is made.

Step 4

If the offer is approved along with the selected options, service and sales contracts are signed.

Step 5

The manufacturing process is started.

Step 6

Step 7

The samples produced during the manufacturing process and before delivery are preserved and shared with the customer.

Step 8

Once the manufacturing work is completed, the machines are made ready for shipment.

Step 9

At the end of notification of the completion of production and preparation for shipment, the customer carries out the transfer process himself from DENK Machinery manufacturing center to his own location.

Step 10

When the contractual installation conditions are met, the machine installation process is carried out with the DENK Machinery service team and the machines are put into operation.

Step 11

The customer and the user team are given training on the use of the machines.

Step 12

The delivery form is signed between DENK Machinery and the customer and the after-sales work process is started.

Step 13

In the after-sales process, feedback is requested from the customer on a monthly basis.

Step 14

Additional development and maintenance services are continued if necessary.

GET IN TOUCH